David R. Beck, Knifesmith LLC

Call Us: +1-610-670-5319

"Fine Cutlery for the Adventurer"

The Original Beck Tracker/WSK (Wilderness Survival Knives)

Click on thumbnails below to enlarge & for captions of features & options available for our WSK knives.

-----------------------------------------------------------------------------------------------------------------------------------------------------------

Tracker/WSK knife models & options:

Tracker/WSK knife availability.

Our Tracker/WSK knives are entirely hand-crafted & laborious to produce. All are made-to-order so we normally don't have any in stock for immediate purchase. Only about 24-30 total Tracker/WSK knives are made per year. Once our quota is full, no additional orders will be accepted until the following year.

*Refer to our "Finished Knives For Sale" page to view all knife models currently available for immediate purchase.

(Right): John "Lofty" Wiseman

Author of the "SAS Survival Handbook" A legend, personal friend, and proud user of one our model "G" WSK knives.

Hope to see you on the trail.

David R. Beck on an adventure atop Angel's Landing, Utah

Tracker/WSK blade anatomy

(A) Draw Knife Edge: The sharpest, & most delicate edge for

general carving, shaping & scraping. Originally hollow

ground, but later changed to a flat-grind (shown) to provide

greater edge support.

(B) 1/4-Round: Used as a gut hook & for carving/scraping trap

parts & arrow shafts.

(C) Hatchet: Flat-ground for chopping, scraping & the only

edge that should be used when splitting woods. Correctly

angled so the strongest part of the blade forward of the

1/4-round" delivers the impact for greater edge safety &

penetration.

(D) Saw Teeth: "Swiss Army" type staggered tooth design is

self-cleaning & aggressive cutting on both the pull & push

stroke. Used for cutting square notches, or tilt at a 45

degree angle to cut "V" grooves (both used for traps &

snares). The downward angle enables sawing square &

"V" grooves on flat surfaces & stakes for trip & snare wire

channels.

(E) Spine Recess: Specifically designed as a striking point when

splitting woods & for push-carving. The curved surface

enables the blade to be rocked or tilted at any angle & still

receive direct energy into the material being worked.

Recess edges are lightly de-burred to avoid thumb abrasion

while carving but can be requested with sharp edges if

needed for scraping tasks.

Although additional benefits have been discovered by others, the anatomy details to the right explain what these knife features were originally designed for.

-------------------------------------------------------------------------------------------------------------------------------------------------------------

Answers to Frequently Asked Questions Regarding Tracker/WSK knives:

* Basic care & use tips are supplied w/every knife, but should a customer not find an adequate answer in the printouts supplied, please contact us for more info.

We're happy to share info & assist our customers in any way we can.

* Our knives are designed to be efficient cutting tools & should be treated as such. They are designed to cut wood, fiber, flesh & similar materials. Although plenty

strong for their intended purposes, they are not indestructible. Our knives are tested beyond the standards of reasonable use to help ensure user safety under

"normal" conditions, but, as with any knife, the more unnecessary abuse your knife receives, the greater risk of premature wear, damage, or injury.

* Chopping/splitting should ONLY be done using the hatchet edge & not the finer draw knife or 1/4-round edges.

* Don't chop bone, & never cut, or chop directly on the ground to avoid edge damage.

* Don't beat on the saw teeth! Although they will hold up well, damaged saw teeth can be very costly to fix & will often alter the appearance of the blade.

* Batoning, or the splitting of wood by pounding on the back of a knife is a task which is common practice today rather than reserved for true survival situations.

We do not recommend batoning only because your interpretation of what may be acceptable force could be quite different from what our knives are tested to

endure. A true, survival situation is one thing, but if you need to split firewood or build a cabin use an axe & your knife will thank you.

* Don't throw or use your knife as a pry bar. (NO, our knives are not designed to fly straight like seen in the "HUNTED" movie.)

* Keep your blades clean & oiled, or better, waxed for those in wet or coastal environments to help ward off rust.

* Don't use diamond stones or grinders for sharpening. On carbon steel blades these remove unnecessary material & lessen blade life. We recommend a hard

Arkansas stone w/light oil or water. For the finest edge maintenance, a simple stropping on leather w/a little fine rouge to polish is generally sufficient.

The key to a sharp edge in not the removal of metal but keeping the edge finely polished.

Stone use should be reserved for very dull, overworked edges, or for removing minor nicks & edge imperfections.

* Apply common sense in use & your knife will give you a lifetime of dependable service.

* Refer to the printed materials your receive with your knife & our "Terms, Conditions & Warranty" page for more info on recommended use, services & product

coverage.

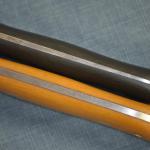

(Left) Wet-sanded vs. blued finishes.

*Note: For 2026, all Tracker/WSK knives are only available with a fine wet-sanded finish.

Blued blade option not available.

(Left) "Type-1" WSK sheath: (Example shown fully-dressed out with all options &

a Scout "companion" knife added to demonstrate set-up capabilities).

Options: (*All add-on options come with blackened steel mounting screws.)

(A) Mounting holes: Unlined but coated inside w/a protective finish. No charge.

Automatically installed for options ordered, or request full-series for more versatility.

(B) 1" Horizontal-carry "scout" loops w/D-rings (2oz.) = $20.00 (per set of two)

(C) 1" Mounting straps to add companion knife or pouch (2oz.) = $20.00 (per set of two)

(D) Brass-lined leg tie/lashing holes = $15.00 (per two)

(E) Full mounting package (includes options A, B, C & D) 4oz. = $45.00 (best deal)

(F). #FRL 3/8 x 1-1/2" Kydex ferro rod loop w/mounting screws (1/2oz.) = $20.00

*Spare mounting screws (contact to order right length) = $0.50 (1 screw & 1 post).

*See below for info on adding a companion knife.

(LEFT) #G2WSKHD Model "G" Gen2 Tracker/WSK knife:

Our personal favorite. Single-position grip enhances ease of handling. Considered a working-man's Tracker geared more for general survival/bushcraft use.

Shown with a wet-sanded finish & unpolished OD green linen Micarta handle w/std. stainless steel Loveless bolts & lined lanyard hole. 1/4 x 7-1/4" differentially heat treated 01 high carbon steel blade w/flat-ground bevels, standard saw teeth & tapered tang.

12-1/2" OAL. Carry wt. approx. 1lb. 13oz.

WE ARE NOW EXCEPTING A LIMITED NUMBER OF ORDERS

Price = $1,625.00 + shipping.

Above: A Dave Beck model "C" Gen1 Tracker

knife as made for the "HUNTED".

Sheath styles available our knives:

* The prices for all knives include the cost of our Type-1 sheath ("Basic-style" w/out mounting holes & "scout" loops).

You can build onto the sheath by adding options you want at an extra cost.

Tracker/WSK sheaths are crafted from 10/11oz. molded black bridle leather. All other sheaths are 8/9oz. molded bridle leather.

*Sheaths are presently only available in durable black bridle leather but we have plans to add brown leather for 2026.

*We can fabricate new sheaths for existing knives made by us, but because every sheath is molded for each individual knife to ensure

the best fit, it is required that you send us your knife in order to have a sheath made.

Note: We no longer produce the Wolverine, Traditional & Type-2 sheaths. If our Type-1 style sheath doesn't fit your needs & you

have another sheath craftsman you'd prefer to use, we can sell our Tracker/WSK knives without a sheath at a discounted

price less our sheath cost.

< Left: Type-1 sheath. "Basic" version.

Fixed belt loop w/modular capabilities.

Specify right or left hand version when ordering.

Can be modified for horizontal "Scout" carry & "piggyback"

attachment of a smaller companion knife sheath or pouch.

*Replacement sheath cost (If purchasing for an existing knife)

12oz. Price = $95.00 (+shipping & any added options)

*See below for available add-on options at an extra cost.

How to order:

1. Email us with your name, mailing address & phone number.

2. Include the knife model, handle material & finish, right or left-hand sheath orientation, & listing of any available available

options you'd like to include. We'll reply within 24hrs. to confirm placement of your order, your order details, what the total

cost will be when completed, & an estimated completion time when your knife will be finished.

3. NO deposit is required to place an order, but payment must be received in full within 7-days from the date you're notified

your knife if finished & ready to ship. You'll receive a progress update about a week or two before completion & notice when

your knife is finished. Payment method would be arranged when you receive your order completion notice.

< Left: An original "Medicine Blade" produced by

Ed Lombi.

(LEFT) #C3WSKHD (Model "C" Gen3 Tracker/WSK knife):

Our most popular model "C" pattern featuring all the upgraded design performance enhancements requested by professional users. 2-position grip for user safety under more demanding conditions. A better "combat/survival" design.

Shown with a wet-sanded blade finish & unpolished black linen Micarta handle w/std. stainless steel Loveless bolts & lined lanyard hole. 1/4 x 6-3/4" differentially heat treated 01 high carbon steel blade w/flat-ground bevels, standard saw teeth, tapered tang, & dual-position grip handle. 12-7/8" OAL Carry weight approx. 1lb. 13oz.

WE ARE NOW ACCEPTING A LIMITED NUMBER OF ORDERS Price = $1,700.00 + shipping.

Handle material choices:

(Note: Handle samples shown demonstrate typical color representation from our suppliers, but be aware that exact color tones can sometimes vary slightly from one manufacturer's batch to the next.)

*Handles are secured by epoxy AND stainless steel Loveless bolts w/lined lanyard holes.

*Linen & burlap Micarta handles come std. w/a finely-sanded but unpolished finish for better grip & less glare, but upon request can

be polished at no extra cost. Paper Micarta & RichLite scales are made std. with a polished finish for the best appearance, but can be

left unpolished upon request. Handle polishing will highlight more color but can create a slightly more slippery grip.

< Black linen Micarta

< OD Green linen

Micarta

< Tan linen Micarta

(Not presently available due to manufacturer dye quality issues)

< Green & black

linen Micarta

< Maroon (burgundy)

linen Micarta

(*$10.00 Extra cost)

< Burlap Micarta

(*$15.00 Extra cost)

Above: Colored handle spacers: Add $10.00

Available in black, white, red or blue.

Above: Polished black paper Micarta

Above: Antique (linear) "ivory" paper Micarta

For those searching for a real "Tracker" knife, we are the premier maker of the Tracker/WSK (Wilderness Survival Knife).

The original concept was conceived by Rob Russon & produced by several makers during the early '80's with the most notable being the "Medicine Blade" crafted by Ed Lombi.

All our Tracker/WSK knives are produced with the following features:

*Every knife & sheath is entirely hand-crafted by David R Beck & we're proud say everything is "MADE IN THE USA".

*Differentially heat-treated 01 high carbon steel blades for superior edge retention & ease of sharpening in the field.

All new Tracker/WSK knives now come std. with fine wet-sanded blade finishes. WE NO LONGER OFFER BLUED BLADES.

*Hand-cut, non-clogging "Swiss Army" style staggered saw teeth for aggressive cutting on both the pull & push stroke.

*Ergonomically-shaped handles for extended use comfort & enhanced grip, secured by strong stainless steel Loveless bolts & a

lined lanyard hole.

*Hand-crafted sheaths wet-molded from durable leather, double-stitched for strength, & coated with a protective oil/wax finish.

*You select the handle material & sheath add-on options to customize a knife kit to suit your personal needs.

*All hardware (snaps, screws, rivets, D-rings, etc.) are made from durable Mil-spec grade components.

*Prices for all knives include the cost of a "Basic" styled sheath. Sheath upgrades & add-options are available at an extra cost.

*All knives come with our 5-day money-back satisfaction guaranty, & our Limited Lifetime Warranty.

Above: RichLite "CBM" (Choc/Brn/Maple)

Polished (similar to paper Micarta)

WARNING FOR THOSE THINKING ABOUT BUYING OUR KNIVES ON EBAY!!

Beware of forgeries of our knives, especially Tracker/WSK knives being sold on ebay!

These are often advertised with pics stolen from our web site to deceive buyers & are often listed for sale by Pakistani companies. If the source says Pakistan, they are most likely criminals advertising stolen & false information to deceive buyers & steal your money. Our advice is to never buy a knife on Ebay without first contacting us & only buy from reputable sellers, or from the craftsmen themselves.

AND, only buy American-made products to support our small businesses & country. If you're ever unsure if a knife you're looking at in any listing was made by us please contact us & we'd be happy to donate our time to authenticate any knives in question.

In 1989, a more professional-grade tool was in demand, & under the direction of Tom Brown Jr., we were tasked to begin supplying military personnel & the students of Tom's wilderness tracking, survival & nature awareness school with our Tracker knife versions featuring significant design improvements to enhance function as a more efficient survival tool. Although a lot of documented history & facts are on record substantiating our design contributions & management of this project, much skepticism continues to exist among "armchair experts" who know little of actual facts. It is of historical importance to note that we were the first & only maker to own the TRACKER knife trademark issued to us in 1993 by the US Patent & Trade Office, & we were the original designer & maker of not just the famous model "C" pattern & numerous other variations, but we also designed & made the actual model "C" Gen1 Tracker knife used by Benicio Del Toro in the 2003 Paramount Pictures film the "HUNTED" which started the Tracker knife craze. We were also the first to incorporate the non-clogging Swiss Army type staggered saw teeth into the Tracker knives & coin the name "WSK" (Wilderness Survival Knife) to this knife design in 2003.

With now over 36-years of making thousands of Tracker knives entirely by hand for outdoorsmen & Elite military personnel, our knives have been field-proven around the globe not only in real-world survival but in many armed conflicts over the past several decades. Although we don't claim the Tracker knife concept is the best design for all & for all purposes, as all stand-alone designs present compromises, we can say we know Tracker knives better than anyone, & through the many years of refinement & field service, we have raised the bar on the design's capabilities earning our knives a solid reputation of being the gold standard by which all others are compared.

Today, all our Tracker/WSK knives continue to be entirely hand-crafted at our workshop to ensure the highest quality & dependability. If you're interested in the Tracker knife concept, our knives continue to excel above all others & are the most sought after. There are many imitations, but none can match the quality, performance, history, or proven investment security our Tracker/WSK knives deliver, making them a solid choice for users & collectors alike.

Above: Official documentation of our TRACKER knife trademark issued in 1993 by the US Patent & Trade Office.